By dk-tester | 24 November 2023 | 0 Comments

Optimizing Electric Vehicle Batteries with Advanced Testing Solutions

Electric vehicles (EVs) are revolutionizing the automotive industry, offering an eco-friendly and cost-effective solution for modern transportation. However, the performance and longevity of EV batteries remain a concern for many consumers. Without proper maintenance and testing, the batteries can degrade over time, compromising the vehicle's range and reliability. To overcome these challenges, advanced testing solutions are being developed to optimize EV battery performance and enhance their longevity. In this blog post, we'll discuss critical testing parameters for EV battery performance, enhancing EV battery longevity through rigorous testing, adapting to evolving standards in EV battery testing, automated testing systems for high-volume EV batteries, and future trends in EV battery testing and maintenance.

1. Critical Testing Parameters for EV Battery Performance

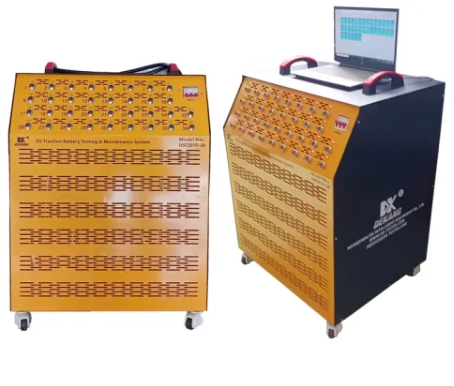

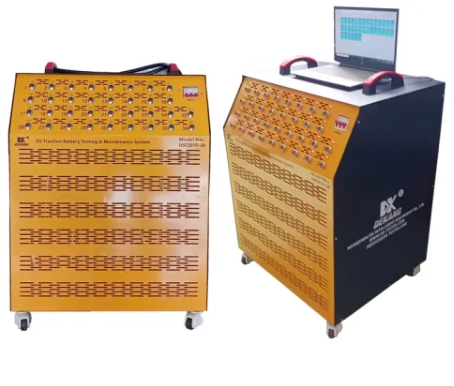

The performance of an EV battery is determined by several critical factors, including its capacity, voltage, and resistance. Testing these parameters accurately and consistently is essential to ensure the battery's optimal performance. Lithium battery testing equipment that integrates advanced technologies, such as impedance spectroscopy and cyclic voltammetry, can provide accurate and reliable measurement results. Moreover, the use of computer-controlled testing systems can enable automated, high-throughput testing of EV batteries, dramatically reducing testing time and improving testing accuracy.

2. Enhancing EV Battery Longevity Through Rigorous Testing

To maximize the longevity of EV batteries, rigorous testing regimes must be implemented. Testing regimes should include environmental and life-cycle testing to simulate the conditions that EV batteries face during actual use. These tests will help to identify any defects or inefficiencies in the battery and inform engineers on how to improve the battery's design. Lithium battery testers can evaluate the battery's capacity, energy, power, lifetime, and other parameters to optimize and validate the battery's performance.

3. Adapting to Evolving Standards in EV Battery Testing

The EV market is continuously evolving, with new regulations and standards emerging regularly. Compliance with these standards is critical to ensure the safety and reliability of EV batteries. EV manufacturers must ensure that their batteries meet these regulations and standards and conduct regular testing to guarantee the safety and performance of their products. Advanced testing solutions provide a versatile and reliable platform for EV manufacturers to meet these evolving standards.

4. Automated Testing Systems for High-Volume EV Batteries

As the demand for EVs continues to grow, the need for automated testing systems for high-volume EV batteries becomes increasingly critical. For instance, automated testing systems can perform multiple tests simultaneously, reducing testing time and increasing throughput. The system also eliminates the need for manual input, reducing mistakes and increasing testing accuracy. Lithium battery testing equipment can significantly improve the scalability and efficiency of EV battery testing.

5. Future Trends in EV Battery Testing and Maintenance

The future of EV battery testing and maintenance involves improving battery performance and maximizing battery life through cutting-edge technologies. For instance, manufacturers are exploring AI and machine learning algorithms that can identify battery defects before they occur, enabling preventive maintenance. Additionally, improved battery management systems offer new opportunities for advanced battery testing and maintenance. As these technologies develop, the reliability and performance of EV batteries will only continue to improve.

In conclusion, optimized EV battery performance and longevity depend significantly on the effectiveness of battery testing solutions. Through rigorous testing regimes, EV manufacturers can identify battery defects and improve their battery design, compliance with evolving standards ensures the safety and reliability, while automated testing systems enable high-volume, accurate, and efficient testing. With technology advancing, the future of EV battery testing and maintenance looks promising, with new and innovative solutions emerging that will improve the performance and reliability of EV batteries. For more information on lithium battery testing and maintenance, contact us at info@dk-tester.com or call us at +86-571-88663349.

1. Critical Testing Parameters for EV Battery Performance

The performance of an EV battery is determined by several critical factors, including its capacity, voltage, and resistance. Testing these parameters accurately and consistently is essential to ensure the battery's optimal performance. Lithium battery testing equipment that integrates advanced technologies, such as impedance spectroscopy and cyclic voltammetry, can provide accurate and reliable measurement results. Moreover, the use of computer-controlled testing systems can enable automated, high-throughput testing of EV batteries, dramatically reducing testing time and improving testing accuracy.

2. Enhancing EV Battery Longevity Through Rigorous Testing

To maximize the longevity of EV batteries, rigorous testing regimes must be implemented. Testing regimes should include environmental and life-cycle testing to simulate the conditions that EV batteries face during actual use. These tests will help to identify any defects or inefficiencies in the battery and inform engineers on how to improve the battery's design. Lithium battery testers can evaluate the battery's capacity, energy, power, lifetime, and other parameters to optimize and validate the battery's performance.

3. Adapting to Evolving Standards in EV Battery Testing

The EV market is continuously evolving, with new regulations and standards emerging regularly. Compliance with these standards is critical to ensure the safety and reliability of EV batteries. EV manufacturers must ensure that their batteries meet these regulations and standards and conduct regular testing to guarantee the safety and performance of their products. Advanced testing solutions provide a versatile and reliable platform for EV manufacturers to meet these evolving standards.

4. Automated Testing Systems for High-Volume EV Batteries

As the demand for EVs continues to grow, the need for automated testing systems for high-volume EV batteries becomes increasingly critical. For instance, automated testing systems can perform multiple tests simultaneously, reducing testing time and increasing throughput. The system also eliminates the need for manual input, reducing mistakes and increasing testing accuracy. Lithium battery testing equipment can significantly improve the scalability and efficiency of EV battery testing.

5. Future Trends in EV Battery Testing and Maintenance

The future of EV battery testing and maintenance involves improving battery performance and maximizing battery life through cutting-edge technologies. For instance, manufacturers are exploring AI and machine learning algorithms that can identify battery defects before they occur, enabling preventive maintenance. Additionally, improved battery management systems offer new opportunities for advanced battery testing and maintenance. As these technologies develop, the reliability and performance of EV batteries will only continue to improve.

In conclusion, optimized EV battery performance and longevity depend significantly on the effectiveness of battery testing solutions. Through rigorous testing regimes, EV manufacturers can identify battery defects and improve their battery design, compliance with evolving standards ensures the safety and reliability, while automated testing systems enable high-volume, accurate, and efficient testing. With technology advancing, the future of EV battery testing and maintenance looks promising, with new and innovative solutions emerging that will improve the performance and reliability of EV batteries. For more information on lithium battery testing and maintenance, contact us at info@dk-tester.com or call us at +86-571-88663349.

Leave a Reply

Your email address will not be published.Required fields are marked. *

POPULAR BLOG

- Boosting Energy Efficiency in Battery Testing: Strategies for Sustainable Operations

- Top 5 Car Battery Testers of 2024: Unleash Peak Performance

- Advanced Battery Testing: Key to Efficient EV Manufacturing and Market Success

- Empowering Industries: Applications of Li-ion Battery Testing Equipment

- Maximize Your Electric Car's Performance with Our Battery Tester

CATEGORIES

TAGS